Trilob lifelineDeformable lifeline for type C anchorage points.

Deformable lifeline.

The TRILOB TM lifeline complies with the safety requirements set out in standard EN 795:2012 for anchorage devices that fall into type C, i.e. horizontal flexible anchorage lines with a maximum inclination of 15° to the horizontal.

The device also complies with the safety requirements set out in the technical specification CEN/TS16415:2013, which establishes the tests and requirements for devices used simultaneously by several users, and also complies with the Italian standard UNI11578:2015.

The lifeline supports are sized to be mounted on reinforced concrete, wood or steel beams, either directly or with special steel counter plates.

The small size of the elements making up the system and its adaptability make the TRILOB TM line particularly popular for use on buildings of historical and architectural value or on narrow paths with many changes of direction, such as the interior cornices of churches.

In the event of a fall, the intermediate elements deform mechanically, absorbing part of the loads that would otherwise be transmitted to the structure. The intervention of an authorised maintenance technician will check the integrity of the system and restore the elements that have fallen.

The device can be used by 4 operators at the same time and complies with the technical standard EN 795:2012 Type C, the Italian standard UNI11578:2015 and the technical specification CEN|TS 16415:2013; it is covered by a 10-year warranty and subject to annual periodic maintenance.

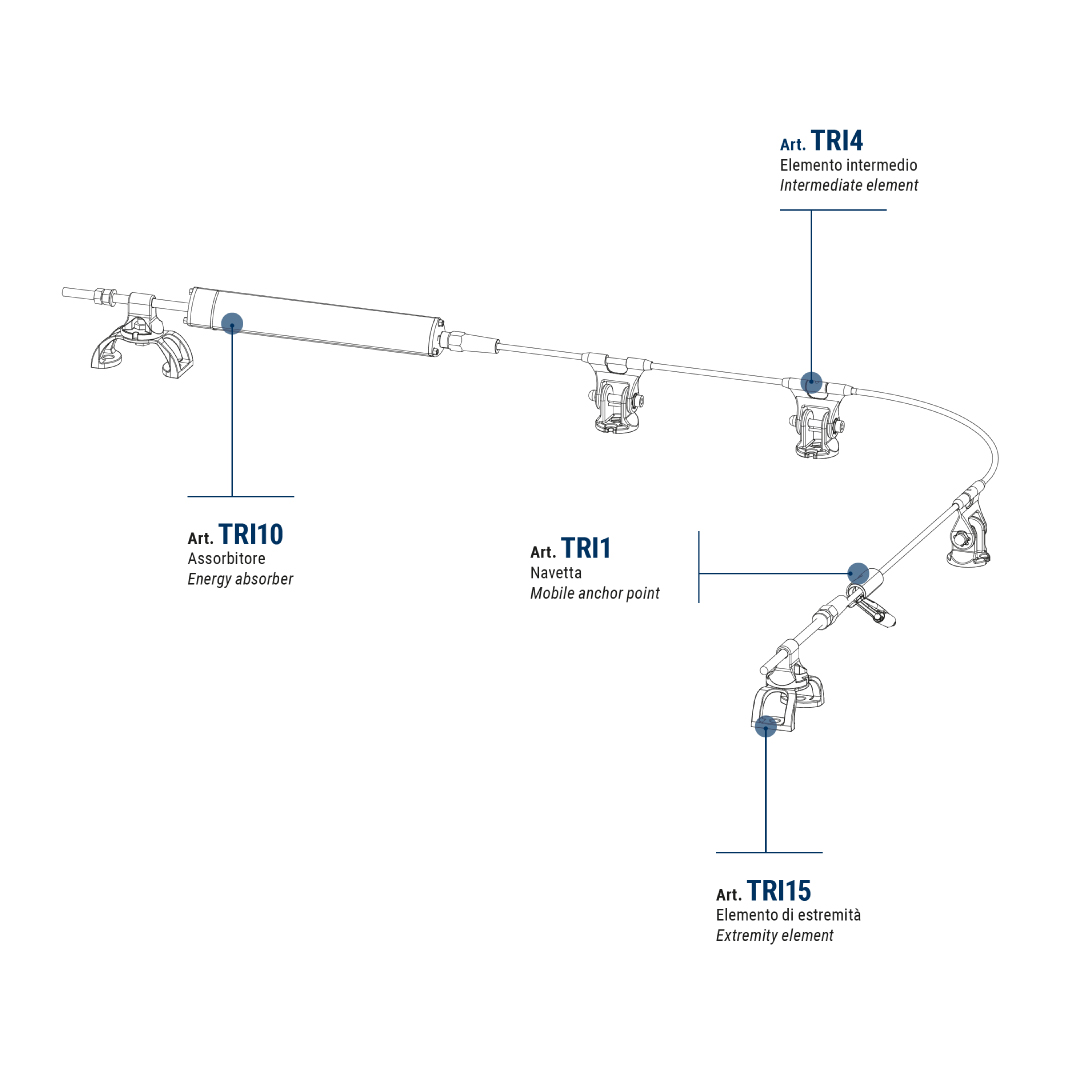

Components

TRI10

Energy absorber

TRI1

Mobile anchor point

TRI4

Intermediate element

TRI15

Extremity element

Accessories

Extremity element

The extremity element is used to create the lifeline starting and end points and

can be secured directly to the receiving structure or by means of standard/special

devices. The articulated head supports the deformation of the cable in case of a

fall; this freedom of movement minimises stresses in all elements that make up

the anchor device.

Material: AISI316

Weight: 0,8 Kg

Intermediate element

Placed at a centre distance between 3 and 15m from the elements that precede

and follow it, the intermediate element allows (by means of a special trolley) a

safe user passage without having to unhook him/her from the flexible anchor.

Material: AISI 316

Weight: 670 g

Dimensions: ø 60×108 mm

Mobile anchor point

Mobile anchor point that allows easy passage of the intermediate elements and

changes of direction, without the connected operator having to unhook. The

supplied connector avoids the accidental release of the mobile anchor point and

the “trolley” can be inserted at any point of the system.

Material: AISI 316

Dimensions: 70 x 50x 30 mm

Weight: 500 g

Energy absorber

The energy/tensioner absorber block reduces the kinetic energy in the event

of a fall and cushions the shock. The energy is dissipated by the work done by

a stainless steel bead that passes through an EPDM cylinder placed inside the

protective casing. Art. TRI10 Also performs the function of tensioner to correctly

position the cable. The fully threaded TTQS M12x200 screw, once inserted in art.

TRI15, acts as tensioner.

Material: AISI 304; EPDM; carter made of aluminium

Dimensions: ø 50×570 mm

Tensioner

The element allows to apply pre-tension on the flexible line.

Material: AISI 316 (A2-70)

Dimensions: ø 22×290 mm

Cable clamp

The cable clamp is an additional element to be inserted in the line whenever a

corner configuration of the device or a line longer than 60m is provided. Placed

inside the intermediate element, allows to lock the cable and keep it taut in the

straight section preceding the curve or in the 60m section.

Art. TRI27, engaged during cable insertion, is equipped with three M6 grub

screws. The adjustment of the grub screw closure allows blocking the strand

sliding

Cable

The cable permits the operator’s anchor on the Lifeline and it allows the motion

throughout its length.

Material: stainless steel

Dimensions: ø 8 mm, 7 x 19 strand

Resistance: > 36 kN

Weight: 0,25 kg/m

Adapter

Adapter to fix the components of the line on the aluminum 80×80 mm poles. The

adapter is connected to the pole with 4 self-tapping 6,3×60 mm screws equipped

with an EPDM washer and gasket.

Adapter

Adapter to fix the extremity element of the line on the aluminum 80×80 mm

poles. The adapter is connected to the pole with 4 self-tapping 6,3×60 mm screws

equipped with an EPDM washer and gasket.

Shelf support

Shelf support for concrete walls, steel structure and wooden structure. The

170×170 mm thick 8 mm shelf is made of cataphorised and painted steel.

Fixing to the structure is guaranteed by 3 M12 bars.

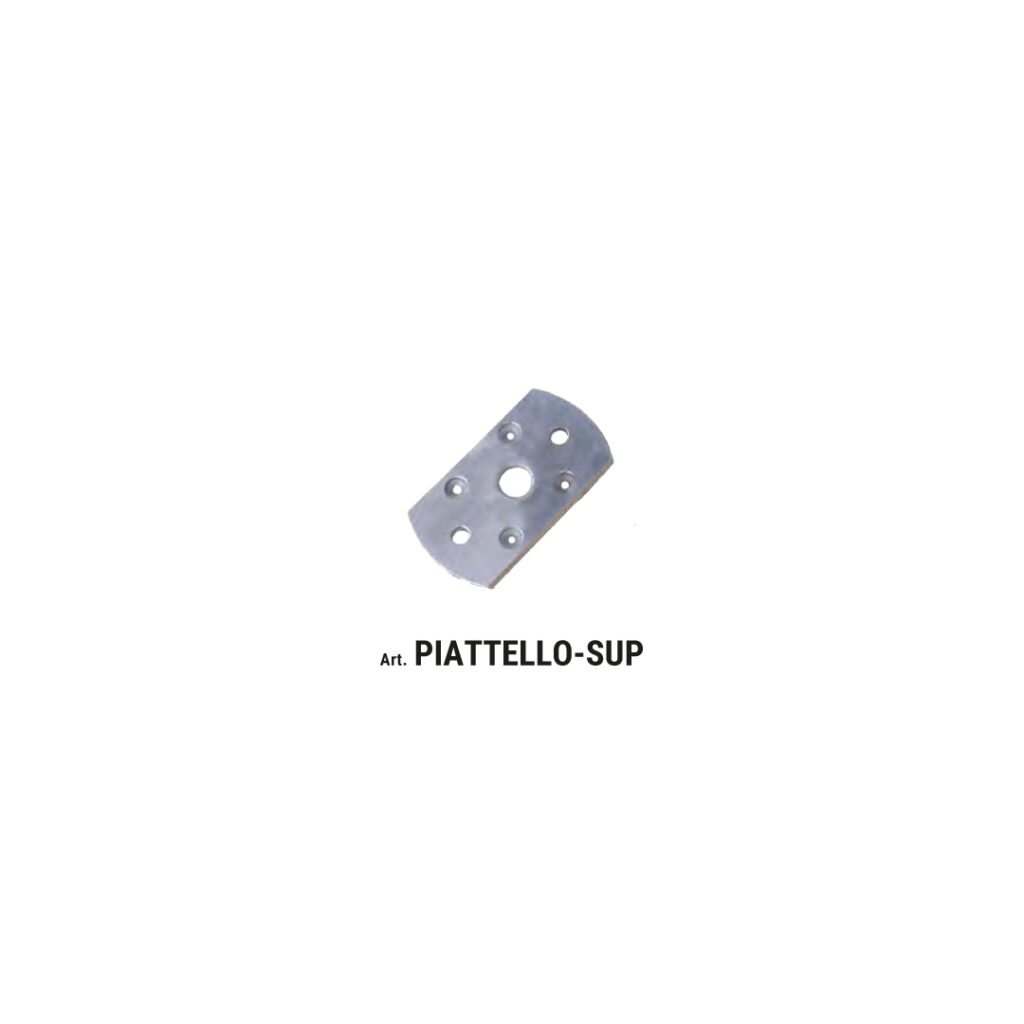

Flat base support

It is used as support for all line components. It is composed by a glass-shaped base

in which it is inserted an aluminum exten-sion fixed by four self-tapping

6,3 x 45mm screws. The entire set is waterproof by me-ans of adhesive foam seal.

Material: steel base with cataphoretic treatment; extension in 7003 T-6 aluminum alloy

Dimensions: 240 x 240 x 460 mm

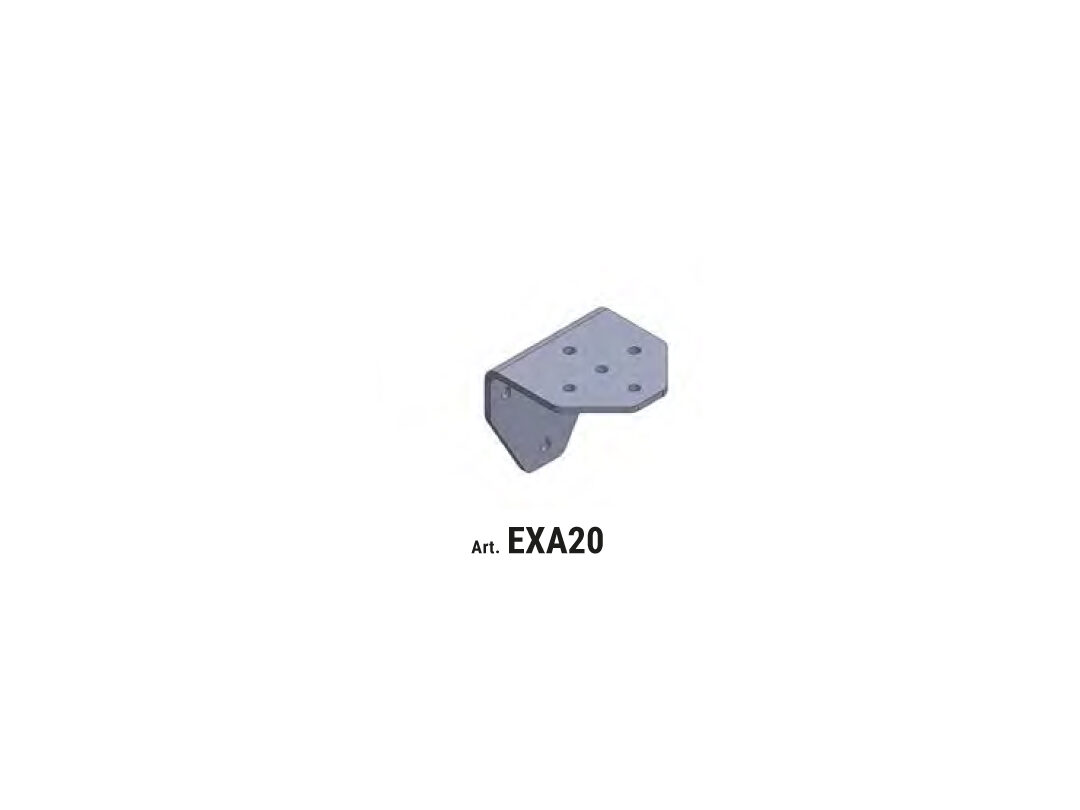

Hut shape base

It is used as support for all line components. It is composed by a glass-hut shaped

base for roofs with 30% slope. An aluminum extension is put inside the base and it

is fixed by four self-tapping 6,3 x 45, screws. The entire set is waterproof by means

of adhesive foam seal.

Flat based support

It is used as standard support for all line components. It is composed by a glassshaped base with a pyramidal section side, having on the inside an aluminum

exten-sion fixed by four self-tapping 6,3 x 45 mm screws. The entire set is

waterproof by means of adhesive foam seal.

Material: AISI 304 stainless steel base; extension in 7003-T6 cataphoretic aluminum alloy

Dimensions: 240 x 240 mm up to 950 mm

Plate for corrugated metal sheet

Support for metal sheet.

The plate is adaptable to different paces,

from 240 mm to 390 mm, and it is fixed by using 12 aluminum peel rivets.

Material: AISI 304 stainless steel

Dimensions: 2 mm thickness; 420 x 420 x 50 mm

Plate for seam roof

Support for seam roof (look at chart). The plate is adaptable to different paces,

from 350 mm to 610 mm, and it is fixed by using 4 S-5 clamps.

Material: AISI 304 stainless steel

Dimensions: 3 mm thickness, 645 x 250 x 30 mm

Fixing: four S-5 clamps

Clamp types

Armature plate for AP100 and AP50

The CP-AP counterplate is studied for applications on support AP100 and AP50. It is

useful when the support must be wrapped with the existing substructure.

Material: cataphoretic steel

Finishing: RAL 7038 painting

Dimensions: 240 x 240 x 10 mm

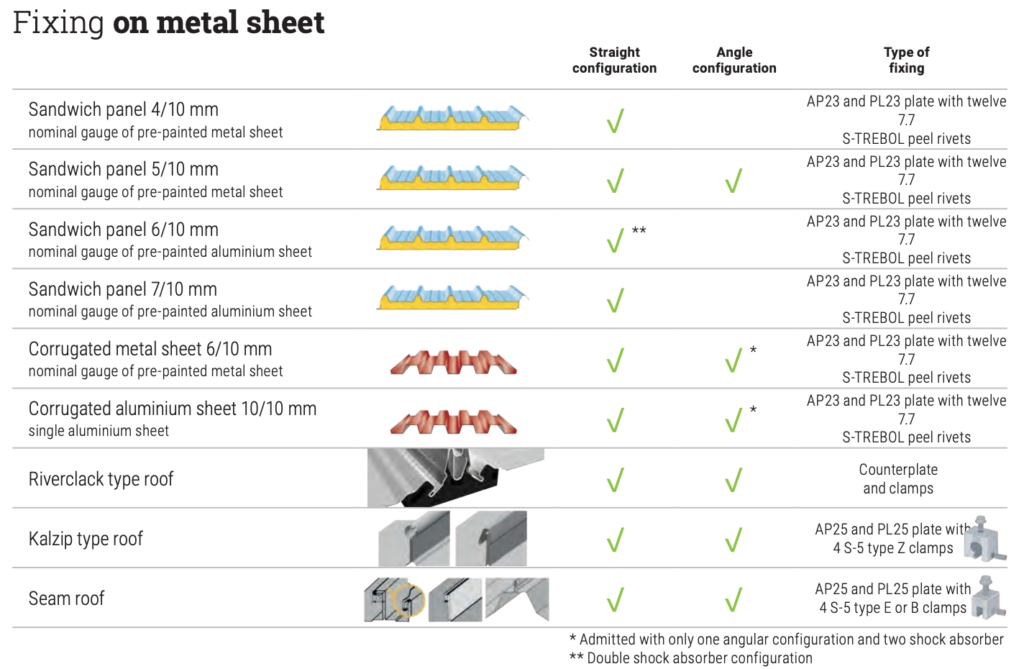

Mounting modes on sheet metal

Advantages

Approved for use by up to 4 operators simultaneously

Large spacing between static restraints, up to 15m

Possibility of direct attachment to structure

Adjustable starting element

Possibility of creating a “closed loop”, with maximum spacing between elements of 4m

Guarantee of constant tension over time, thanks to the plate with inserted SIM card absorber block

Deformability of intermediate elements in the event of a fall

Possibility of making the corner loop without the need for a crimping machine

Simplicity and speed of installation

Reduced loads on structures in the event of a fall

Stamped AISI316 stainless steel elements

Customised design of supports

Minimal aesthetic impact

Ergonomics

Lightness

Modularity

Ten-year warranty

Certifications according to the strictest industry standards

Testing to verify proper installation

Our references