Exagon Lifeline kitRope lifeline for structures with low load-bearing capacity.

Exagon Lifeline kit

Rope lifeline available in practical 15, 30 and 45 m kits.

The EXAGON TM lifeline complies with the safety requirements set out in EN 795:2012 for anchor devices that fall under type C, i.e. horizontal flexible anchor lines with a maximum inclination of 15° to the horizontal, and also complies with the Italian standard UNI11578:2015.

The anchoring device employs a flexible anchor line suitable for structures and roofs with low or reduced load-bearing capacity, thanks to its deformability, which allows it to dissipate the energy generated by a fall.

It consists of a metal cable stretched between two or more elements fixed directly to the receiving substructure or, if necessary, to adequately sized

supports, with an energy absorber mounted at the end of the line, which dampens the energy in case of operator fall.

The passage of the intermediate

elements and corner transmissions takes place by using a simple EN362 connector connected to a double lanyard or a double lanyard that allows

hook-unhook.

All components making up the device are weld-free and have been studied to adapt different types of supports according to the requirements and

to reduce both installation time and the number of different tools required for assembly.

The device can be used simultaneously by 3 operators and complies with technical standard EN 795:2012 Type C and technical specification CEN|TS 16415:2013; it is covered by a 10-year warranty and subject to annual periodic maintenance.

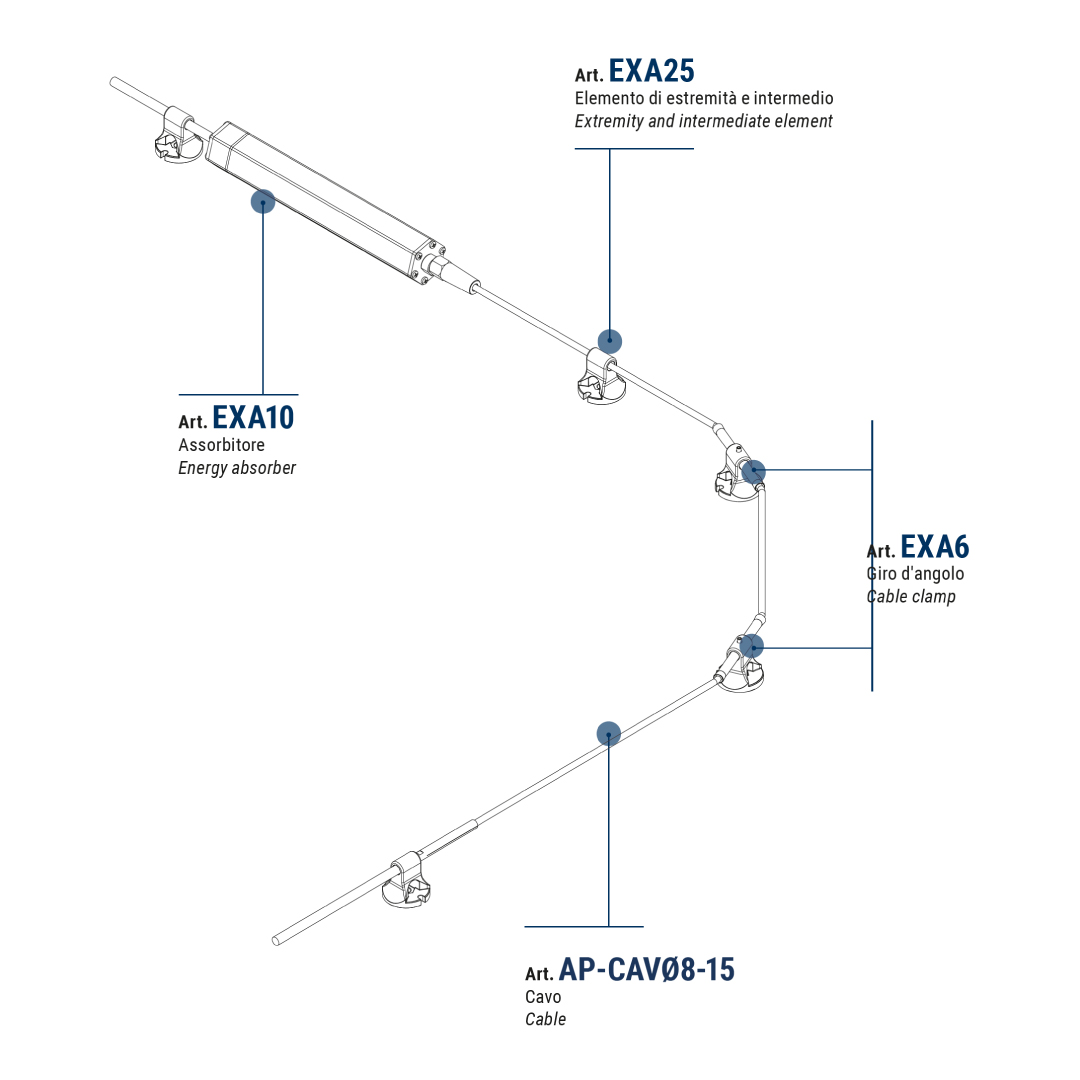

Components

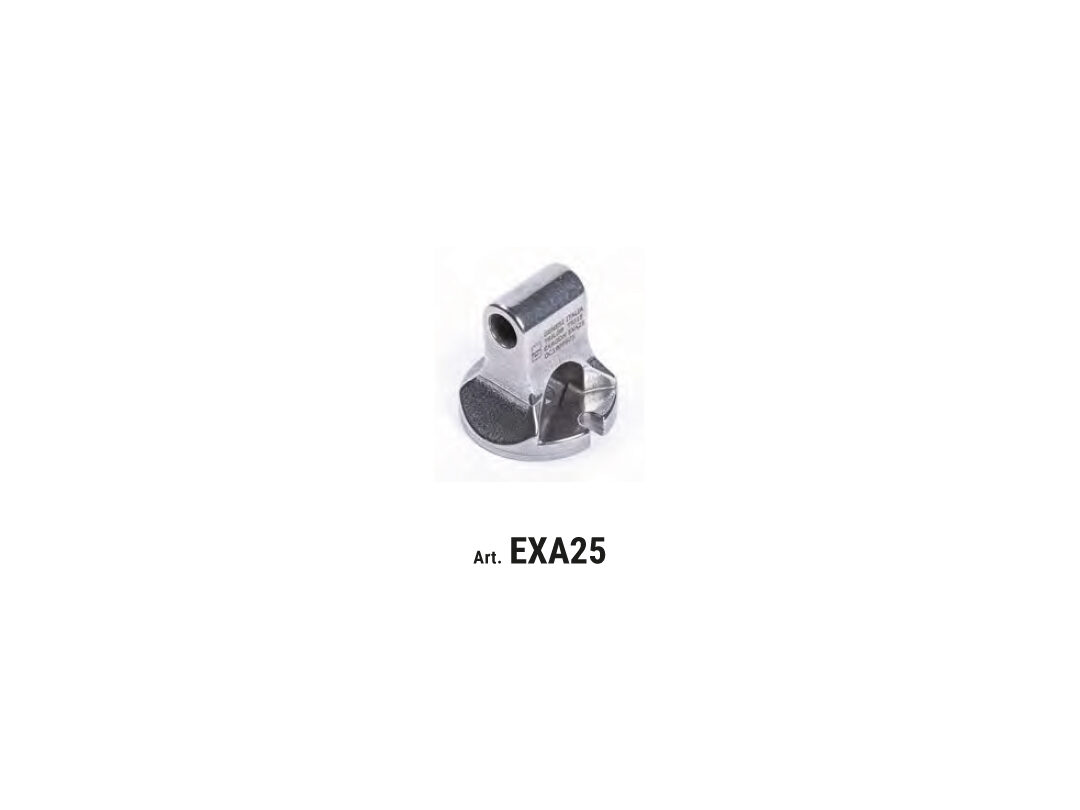

EXA25

Extremity and intermediate element

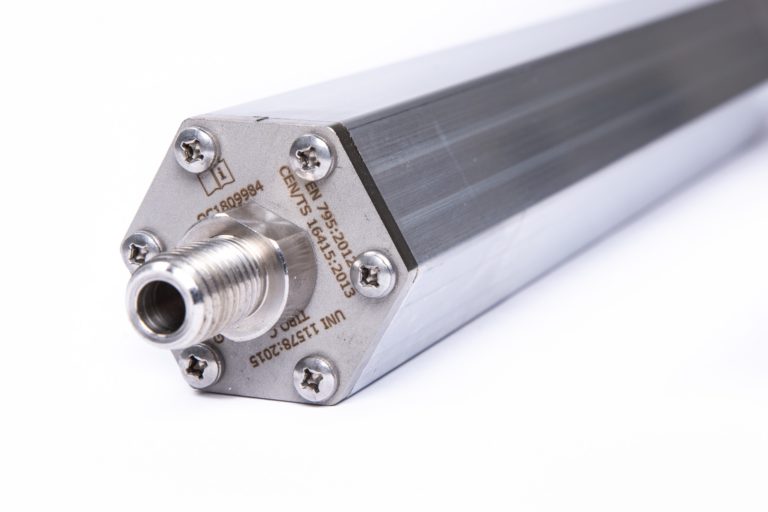

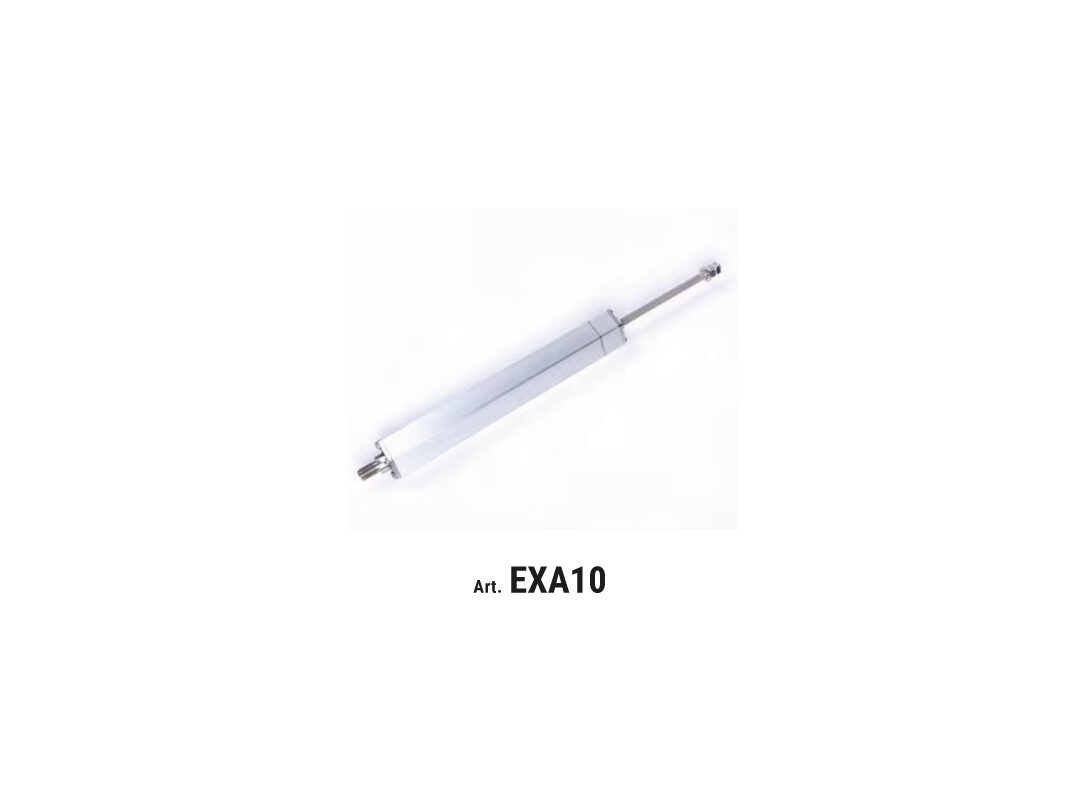

EXA10

Energy absorber

EXA6

Cable clamp

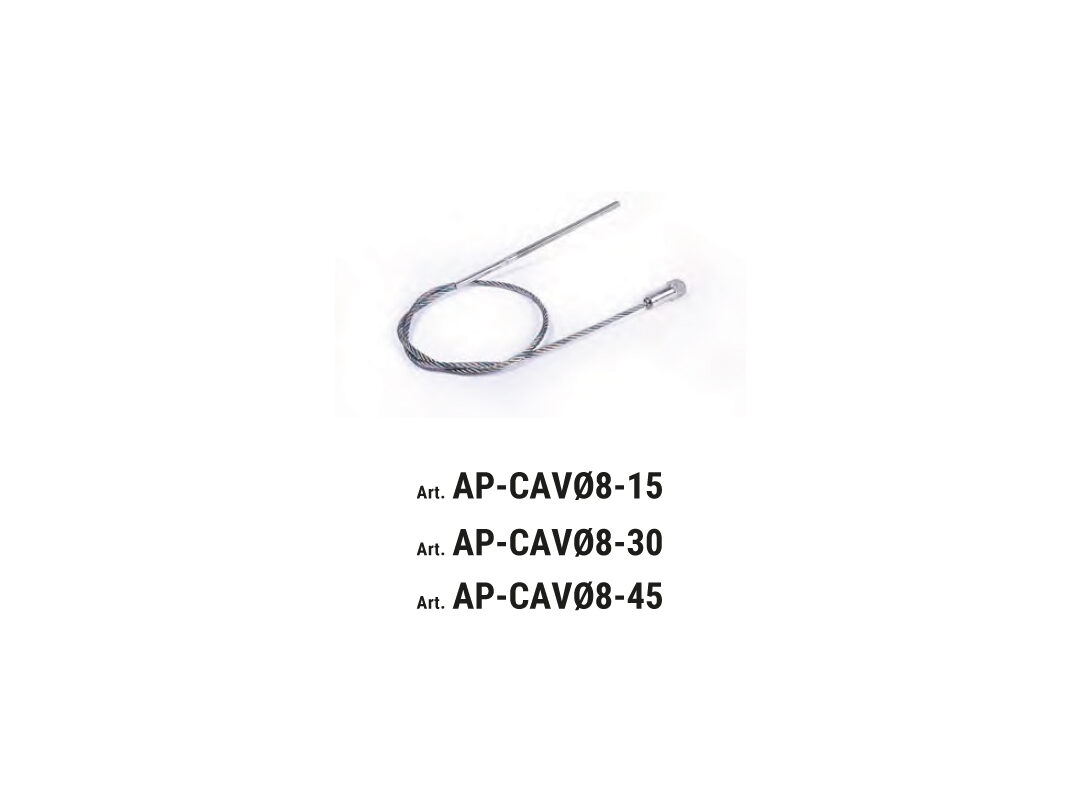

AP-CAVØ8-15

Cable

Accessories

Extremity and intermediate element

The element is used to create the start end intermediate (if necessary, for lines

longer than 15m) of the flexible anchor device and can be fixed directly to the

receiving structure or by means of standard/special supports.

Energy absorber

The energy/tensioner absorber block reduces the kinetic energy in the event of a fall and

cushions the shock.

Cable clamp

The cable clamp is an additional element to be inserted in the line whenever

a corner configuration of the device is foreseen. A suitably flared 1mm thick

stainless steel tube with outside diameter of 12mm is inserted into the EXA25

element to “guide” the cable. The stainless steel tube is locked by an M6x10

stainless steel grub screw.

In the event of a fall the tube deforms, absorbing part of the kinetic energy.

Cable

The steel cable allows the operator to be anchored to the lifeline.

Material: Stainless Steel

15 meters kit

- 2 elements EXA25

- 15 Mt. cable with tensioner AP-CAVO8 -15

- 1 energy absorber EXA10

- 1 Mandatory sign CA00

- Manufacturer’s information note

30 meters kit

- 3 elements EXA25

- 30 Mt. cable with tensioner AP-CAVO8 -30

- 1 energy absorber EXA10

- 1 Mandatory sign CA00

- Manufacturer’s information note

45 meters kit

- 4 elements EXA25

- 45 Mt. cable with tensioner AP-CAVO8 -45

- 1 energy absorber EXA10

- 1 Mandatory sign CA00

- Manufacturer’s information note

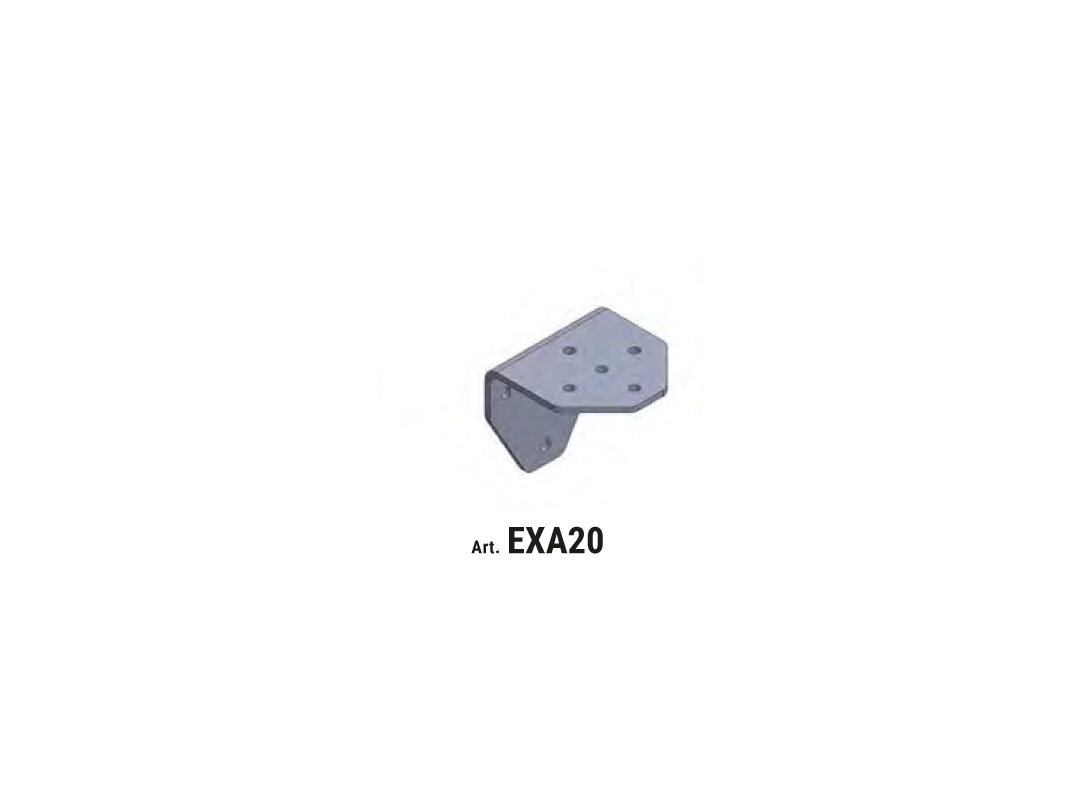

Adapter

Adapter to fix the components of the line on the aluminum 70×70 mm poles. The

adapter is connected to the pole with 4 self-tapping 6,3×60 mm screws equipped

with an EPDM washer and gasket.

Shelf support

Shelf support for concrete walls, steel structure and wooden structure. The

170×170 mm thick 8 mm shelf is made of cataphorised and painted steel.

Fixing to the structure is guaranteed by 3 M12 bars.

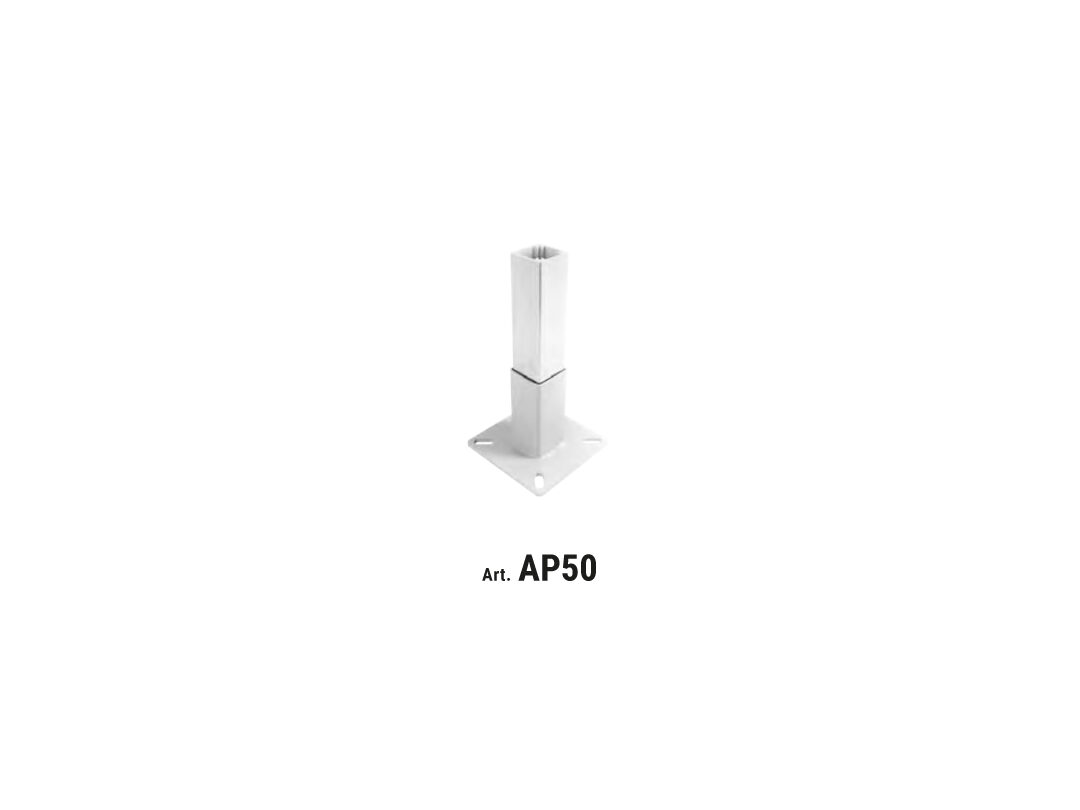

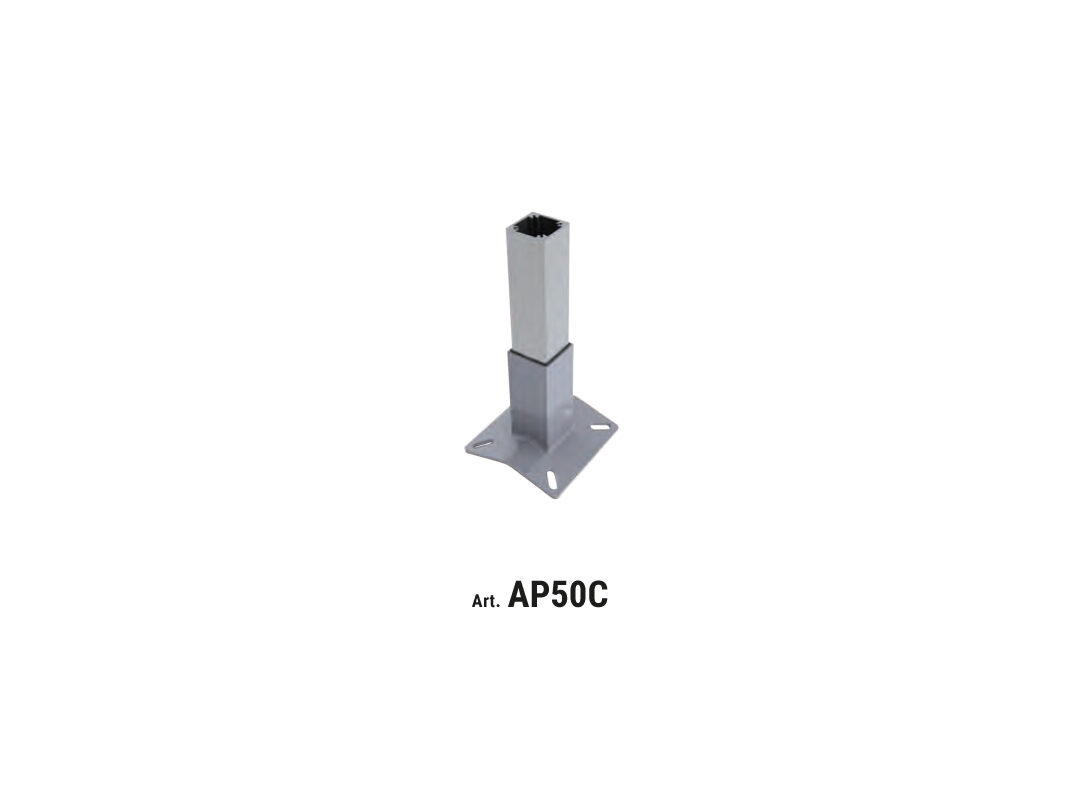

Flat base support

It is used as support for all line components. It is composed by a glass-shaped base

in which it is inserted an aluminum exten-sion fixed by four self-tapping screws. The

entire set is waterproof by me-ans of adhesive foam seal.

Material: steel base with cataphoretic treatment; extension in 7003 T-6 aluminum alloy

Dimensions: 240 x 240 x 460 mm

Hut shape base

It is used as support for all line components. It is composed by a glass-hut

shaped base for roofs with 30% slope. An aluminum extension is put inside the

base and it is fixed by four self-tapping screws. The entire set is waterproof by

means of adhesive foam seal.

Material: steel base with cataphoretic treatment. Extension in 7003 T-6 aluminum

alloy

Dimensions: 240 x 240 x 460 mm

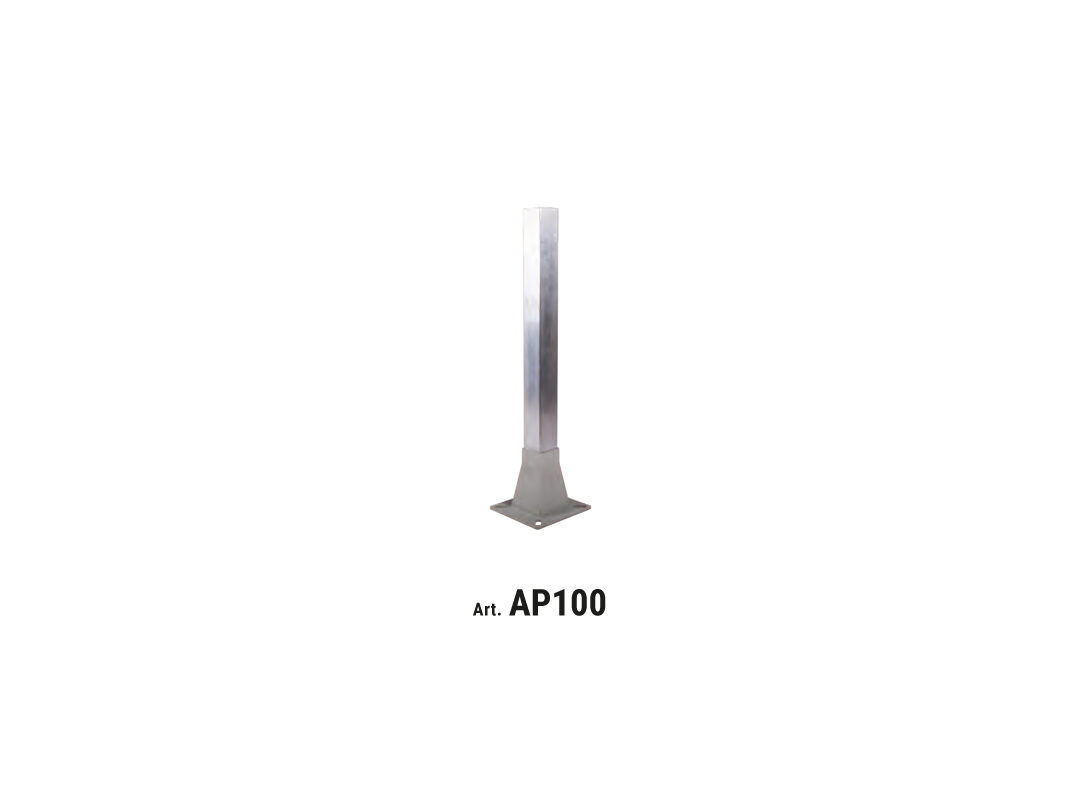

Reinforced flat based support

It is used as standard support for all line components. It is composed by a

glass-shaped base with a pyramidal section side, having on the inside an

aluminum exten-sion fixed by four self-tapping 6,3 x 45 mm screws. The entire

set is waterproof by means of adhesive foam seal.

Material: AISI 304 stainless steel base; extension in 7003-T6 cataphoretic

aluminum alloy

Dimensions: 240 x 240 mm up to 950 mm

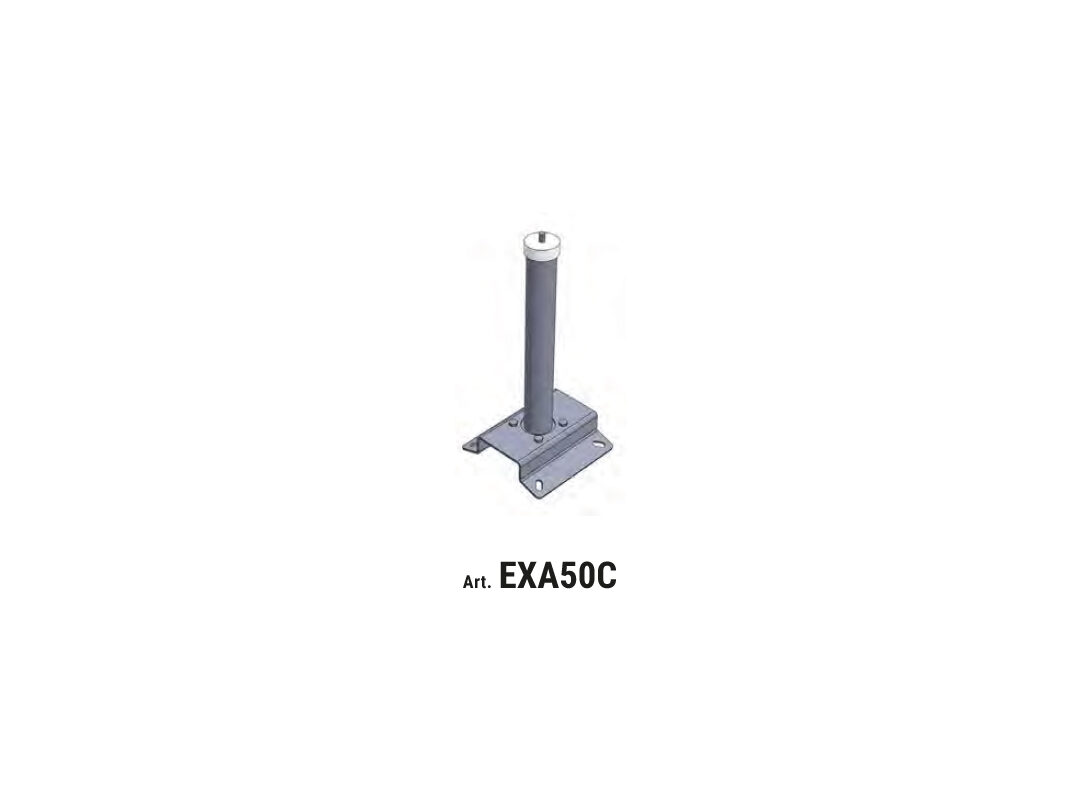

Pole support

Support for steel or concrete / concrete ridges. The support consists of:

- 240x240x50 mm hut base in S355JR steel, cataphorised and painted

- pole in S355JR steel with round hollow section of size Ø 60 mm and maximum

height of 410 mm

The pole is pre-assembled in the special seat of the base with n.4 M10 mm

stainless steel screws with washer and steel nut. The support thus assembled is

connected to the roof by 4 M12 bars.

Pole support

Support for ridges in a double-pitched roof in steel or concrete / concrete. The

support consists of:

- 240x240x65 mm hut base in S355JR steel, cataphorised and painted

- pole in S355JR steel with round hollow section of dimensions Ø60mm e maximum height of 410mm.

The pole is pre-assembled in the special seat of the base with n.4 M10 mm

stainless steel screws with washer and steel nut. The support thus assembled is

connected to the roof by 4 M12 bars

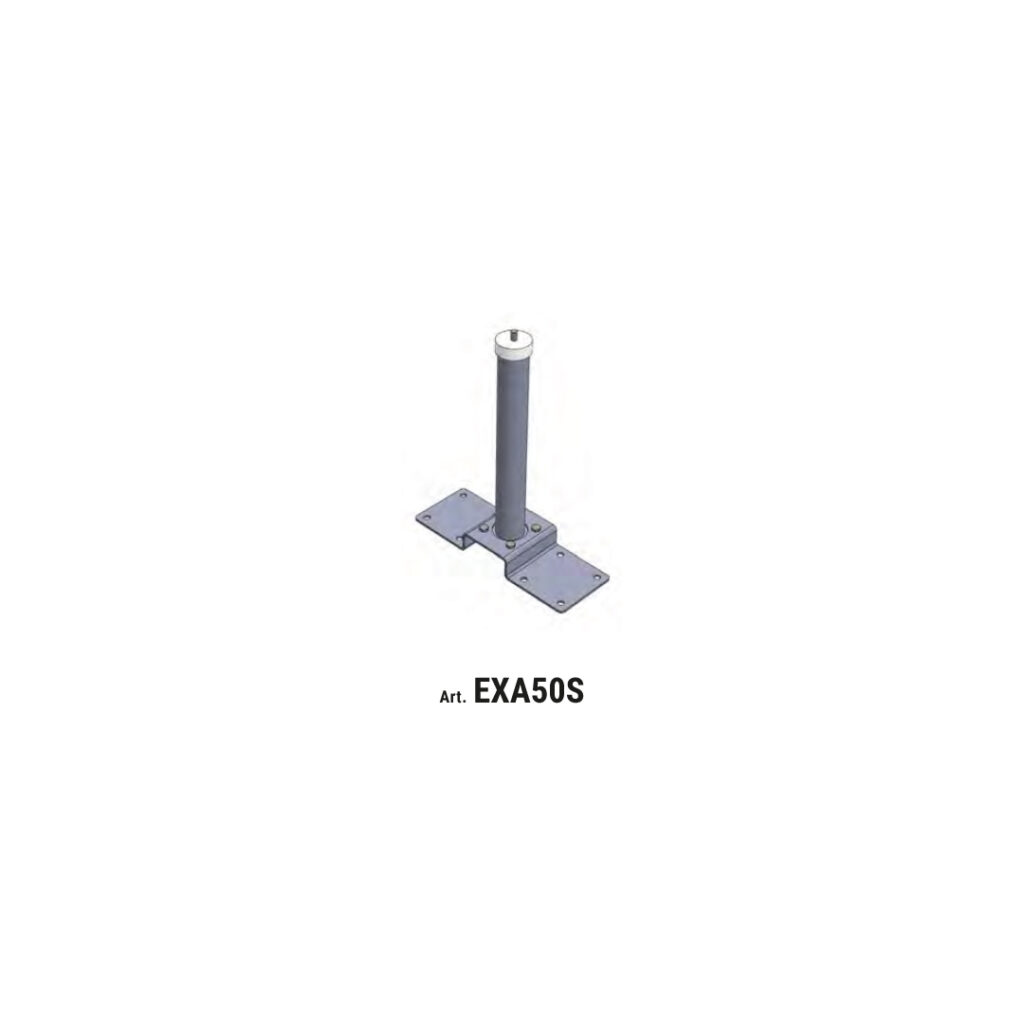

Pole support

Support for wooden ridges. The support consists of:

- 150x420x50 mm hut base in S355JR steel, cataphorised and painted

- pole in S355JR steel with round hollow section of size Ø 60 mm e maximum height of 410 mm.

The pole is pre-assembled in the special seat of the base with n.4 M10 mm

stainless steel screws with washer and steel nut. The support thus assembled is

fixed to the roof using M12 bars.

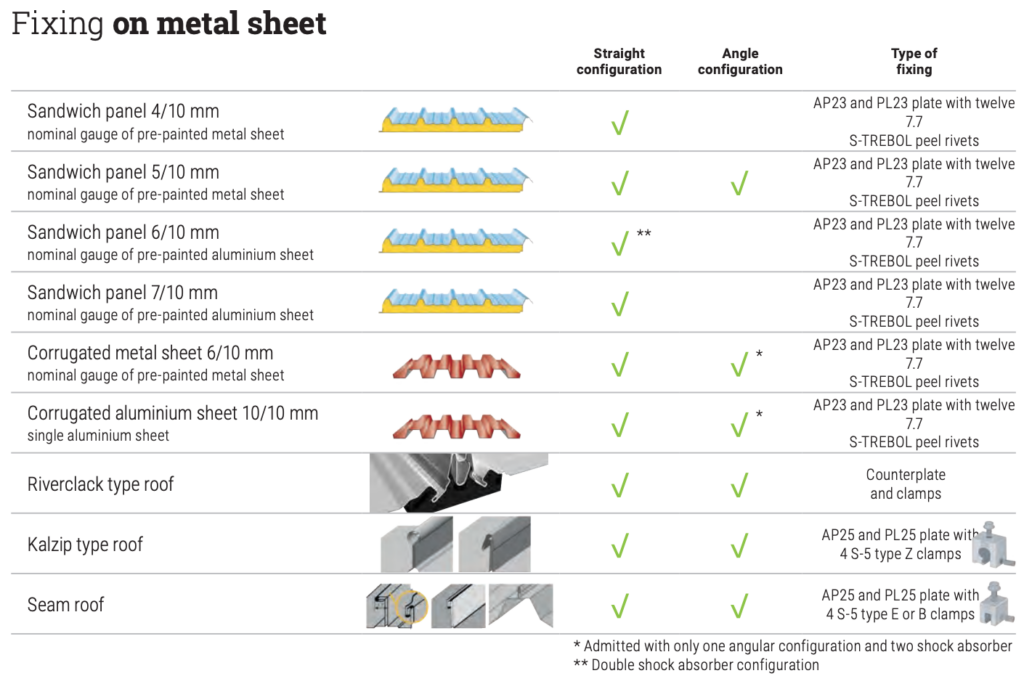

Plate for corrugated metal sheet

Support for metal sheet (look at chart). The plate is adaptable to different paces,

from 240 mm to 390 mm, and it is fixed by using 12 aluminum peel rivets.

Material: AISI 304 stainless steel

Dimensions: 2 mm thickness; 420 x 420 x 50 mm

Fixing: twelve 7,7 aluminum peel rivets, equipped with EPDM washer

Plate for seam roof

Support for seam roof (look at chart). The plate is adaptable to different paces,

from 240 mm to 390 mm, and it is fixed by using 4 S-5 clamps.

Material: AISI 304 stainless steel

Dimensions: 3 mm thickness, 645 x 250 x 30 mm

Fixing: four S-5 clamps

Supports counterplate

Advantages

Approved for use by up to 3 operators at the same time

Possibility of direct attachment to the structure

Guarantee of constant voltage over time, thanks to the plate with SIM card inserted in the absorber block

AISI316 stainless steel elements moulded in series

High-slide corner cable loop

Lightweight and attractive design

Reduced loads on structures in the event of a fall

Reduced installation costs

Customised bracket design

Easy and fast installation thanks to M12 screw/bar fastening

Possibility of assembling the elements without the use of tools

Ergonomics

Lightness

Modularity

Ten years warranty

Certifications according to the strictest industry standards

Testing to verify proper installation